Add-ons

In addition to our line of anticorrosive materials and refractory products, our customers can count on imported products that complement their works.

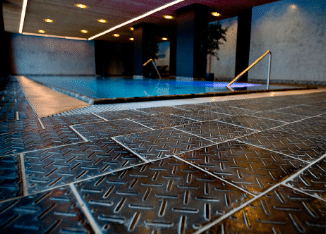

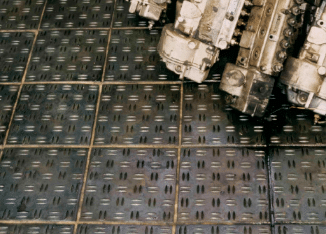

Cast Basalt

Cast basalt for industrial floors with high mechanical impact, tanks and silos for abrasive materials.

It is a natural mineral material that, when melted at 1280 ˚C, can be molded into various final shapes. Due to its characteristics of high resistance to

abrasion, compression and impact, as well as high hardness, low porosity and high chemical resistance, cast basalt is an excellent material for protection against abrasion and wear in places where sliding flow of abrasive materials occurs. See below the main technical data:

- Apparent Bulk Density: 2.9 to 3.0 g / cm³;

- Compressive strength: 300-450 MPa;

- Mohs hardness: close to 8 (diamond is 10);

- Water absorption: 0%.

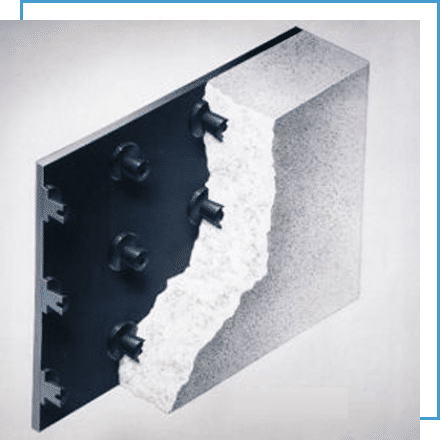

Bekaplast

Bekaplast, a line of prefabricated coverings based on polyethylene and polypropylene. Pre-molded coating based on Polyethylene or Polypropylene and assembled for anticorrosive conformation in the concreting of tanks and channels. With the BEKAPLAST precast coating system,

concrete in the curing phase will be immediately protected against chemical attacks, without the need for subsequent coating.

BEKAPLAST coatings can also be installed for anti-corrosion maintenance in areas where the operation does not allow prolonged stops..

For more technical information visit the literature page and see our folders and catalogs. If you do not find the necessary information, contact our technical team: (19) 3729-3070

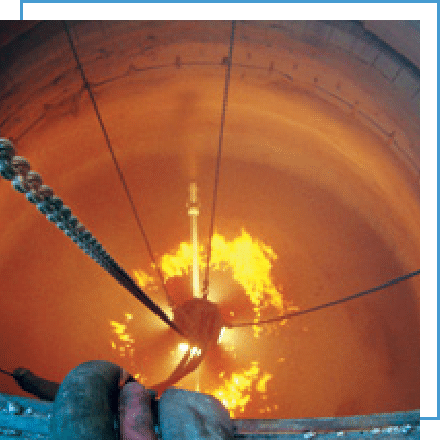

Magneco Metrel

MAGNECO METREL is TECNOLITA's newest partner in the Brazilian market. MAGNECO METREL INC., An American company, produces and distributes special monolithic refractories linked to colloidal silica for applications in the steel, cement, aluminum, ceramic, copper, ferroalloys,

foundry, glass, etc. industries.

The company, founded in 1978, based in Addison, Illinois and has plants in Addison, Illinois; Negley, Ohio; Gary, Indiana; Tianjin,

China and Shildon, England. Metpump® products, developed by her, are used “in situ” through applications for pumping, projection, injection and even pouring.

It also allows special parts to be obtained so that the coating assembly is even faster and more efficient and with excellent dimensional quality.

Metpump® products are materials that allow drying and sintering in a very short time, since all the free water in the material is removed at a temperature of 120 ° C. Worldwide, the Metpump® brand is synonymous with quality, speed, safety, ease of application and recovery of

refractory linings, as it has provided its customers with quick returns, reduced equipment downtime for their recovery andincreased performance.

For more technical information visit the literature page and see our folders and catalogs. If you do not find the necessary information, contact our technical team: (19) 3729-3070

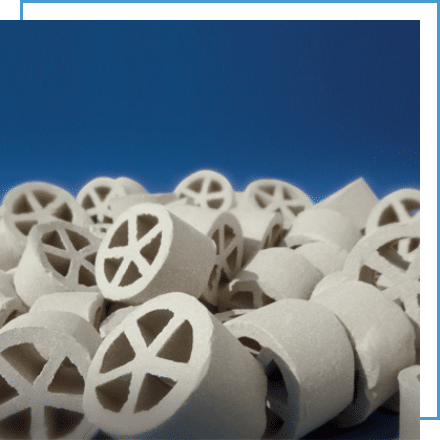

Fillings

Fillings for process columns and catalyst bed supports. NATIONAL DISTRIBUTION WITH INTERNATIONAL QUALITY! The products of the largest European manufacturer of process column fillings and catalyst bed supports can now be found in Brazil.

TECNOLITA Industrial is a distributor of the German brand VFF - Vereignite Füllkörper Fabriken GmbH & Co., so our customers can count on this offer, in addition to our traditional manufacturing lines.

- Fillings of ceramic, plastic or stainless steel

- DURANIT® inert spheres

- Droplet separators (demister)

- Process columns Interior

- Software for basic columns projects

All products are manufactured in accordance with strict German safety standards, and undergo regular tests in the context of DIN EN ISO 9001.