Ceramics Industries

Pottery is one of artifacts production activity from clay, which becomes very…

VIEW MORE

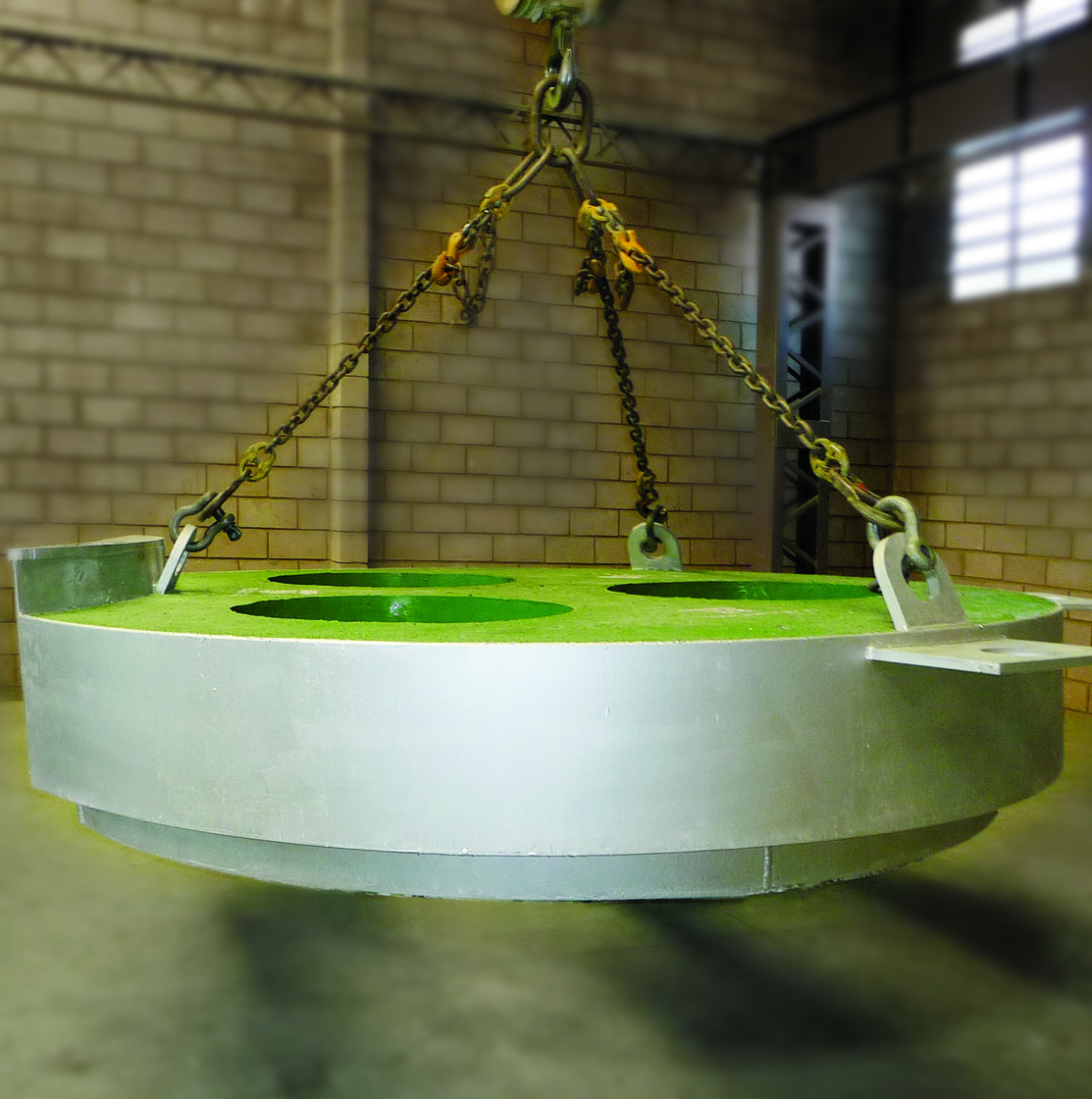

Steel Casting and Cast Iron

In metallurgy, casting is the process of placing molten metal into a…

VIEW MORE

Projects and Equipment Companies

Companies specialized in design solutions and equipment that need our product line…

VIEW MORE

Industries Cement and Lime

The cement industry requires large investments and is subject to cost pressures.…

VIEW MORE

Steel Industries

The steel is a metallurgical branch dedicated to the transformation of iron.…

VIEW MORE