Coatings that combine reinforced plastic applications with special low-porosity ceramics are the highlight of TECNOLITA Industrial’s work (Campinas, SP) at the Horizonte Project, at Fibria Três Lagoas (Três Lagoas, MS).

The coatings used in the factory’s three bleaching towers are the second largest application in the world of this type of product.

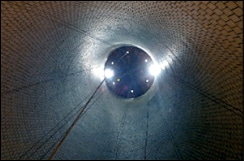

Already in operation, the new pulp mill for the production of Fibria Três Lagoas (Três Lagoas, MS), formerly VCP Três Lagoas, combines the use of composites coverings with vinyl ester resin, reinforced with fiberglass blankets, with the application ceramic tiles in a total area of 4,200 square meters of tiles. It is the second largest set of bleaching towers in the world – 67 meters high, second only to the 70 meter SPC towers (Mucuri, BA), also protected by TECNOLITA Industrial.

Process

The cellulose pulp bleaching stage takes place in three towers three towers of calendered steel plate with a conical bottom. In these towers, the cellulose mass is subjected to the presence of hydrogen peroxide, hydrochloric acid and sulfuric acid, in order to, as the name says, be bleached. The mass, very abrasive, is in constant motion inside the towers. It was necessary to apply an internal anti-corrosion coating to the steel structure and to the upper rail, assembled later.

Corrosion protection

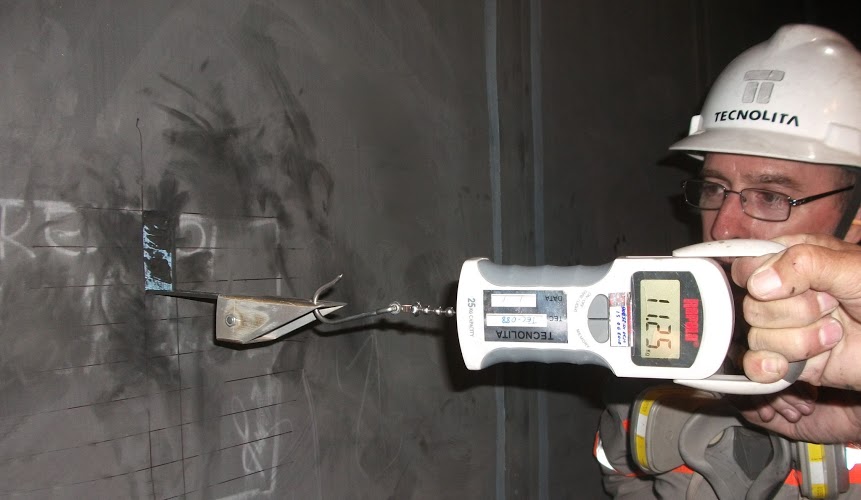

For the anticorrosive coating of the structure, Andritz (Curitiba, PR), the company responsible for the installation, subcontracted the coatings company TECNOLITA Industrial (Campinas, SP), which used coatings based on ester-vinyl resin and fiberglass blankets. For protection against abrasion, imported ceramic tiles with low moisture absorption content were chosen. These plates were installed

manually, with several pieces at key points specially molded, in order to withstand the passage of the dough for several years.

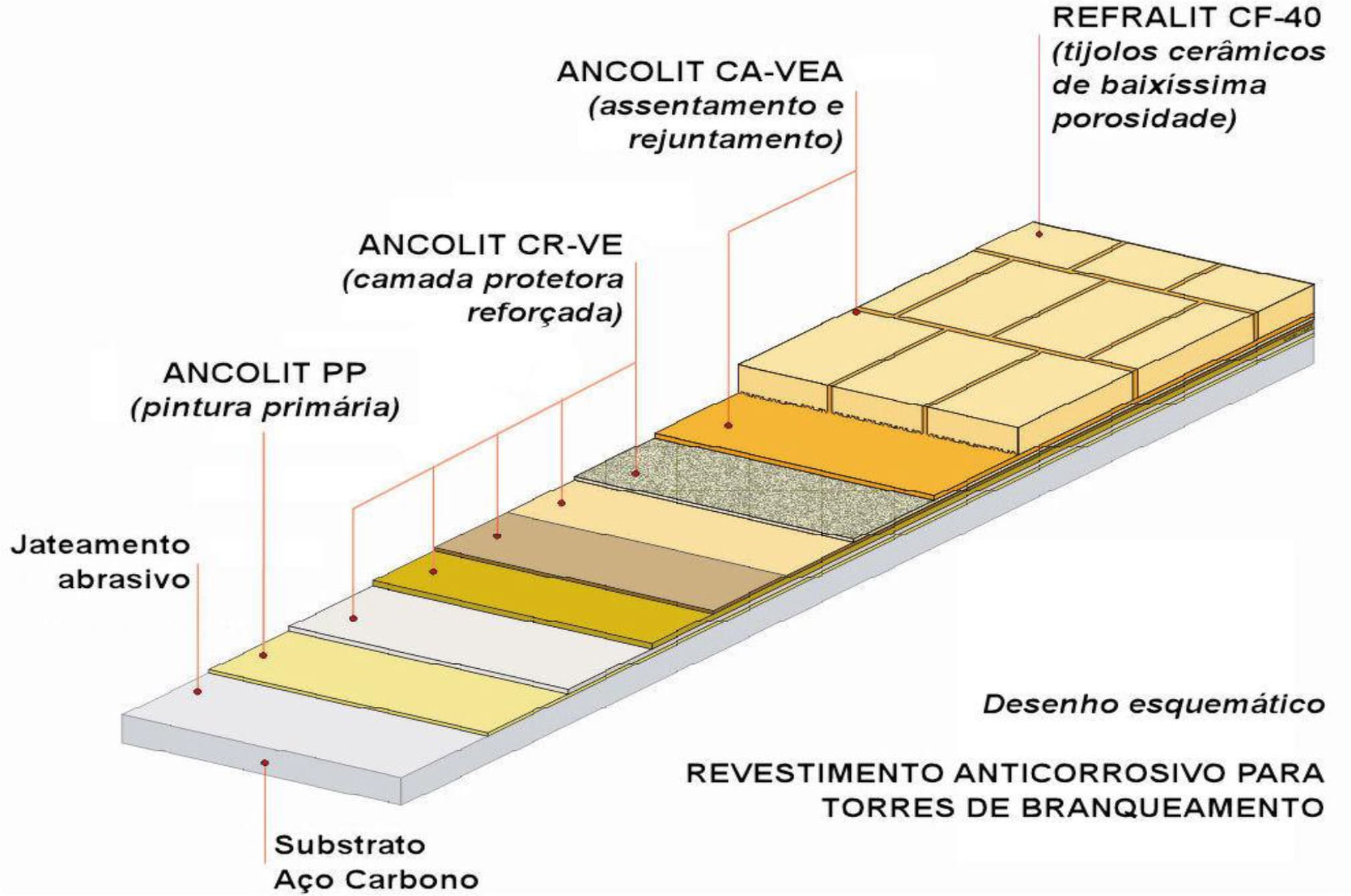

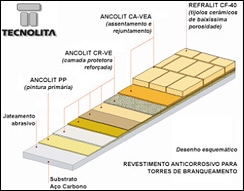

Sandblasting

Due to its size and complexity, the application of coatings on 67m high towers was done through an internal motorized structure. The first phase of the coating work consisted of abrasive blasting, for the preparation (treatment) of the surface. Sandblasting is carried out on both concrete and steel, and serves to remove impurities and create an adequate substrate roughness profile for anchoring the first primer phase, already in ester-vinyl resin. This primer then takes several layers of fiberglass mat laminated with resin. Finally, ceramic tiles are laid and grouted.

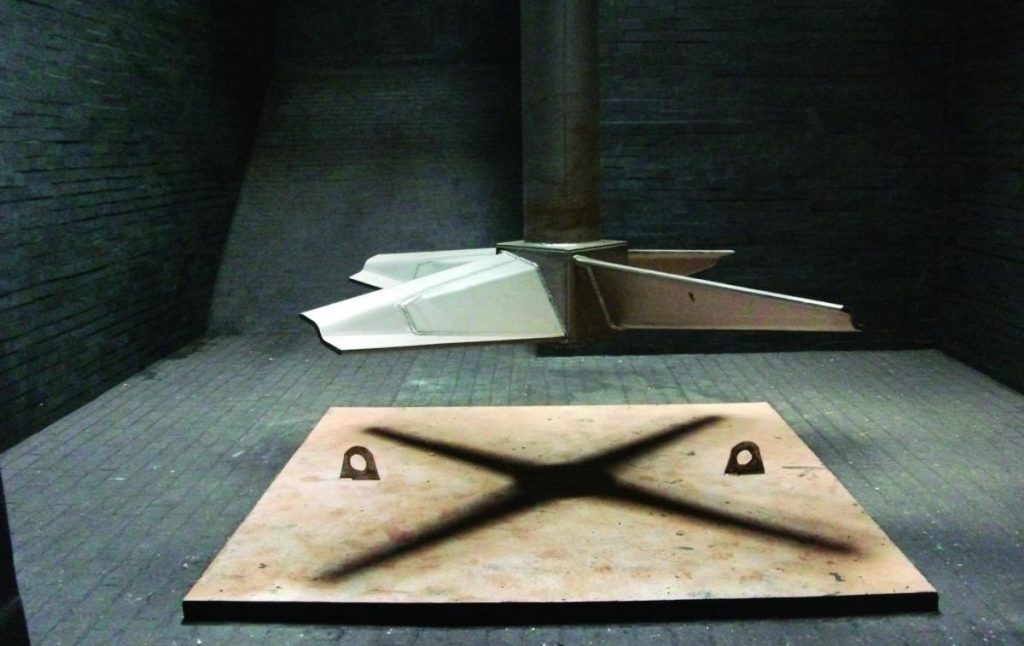

Plates and ceramic parts

Extruded ceramic plates and pieces with “swallowtail” claws on the underside, imported ceramic plates stand out for their very low porosity, a factor that minimizes the friction generated by the flow of cellulose. The creation of special and differentiated pieces, produced according to the individual characteristics of each project, provide the final finish to the set. An example is the outlet for the trough, in which the ceramic pieces have a “J” shape, for greater resistance and tightness. Another example is the leading edge of the tank, in its conical part.