- ANCOLIT CA

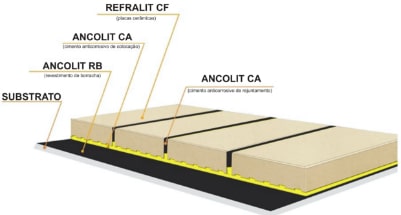

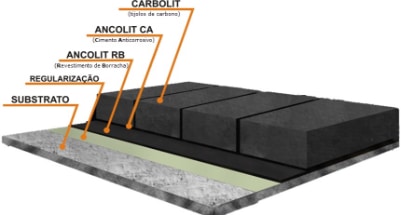

ANCOLIT CA

Anticorrosive Cement Line for laying and / or grouting ceramic or carbon plates and bricks, where each formulation has physical and chemical characteristics appropriate to the application environment.

ANCOLIT CA EP EPNF EPT FU FUC FUCT FUR H PH PHC PS UP VE VEA VEC VET Resin / Load Epoxy / Silica Novolac Epoxy / Silica Epoxy - Tar / Silica Furan / Silica Furan / Carbon Furan / Carbon Furan / Silica HET Polyester / Silica Phenolic / Silica Phenolic / Carbon Potassium silica / silica INSAT polyester. / Silica Vinyl Ester / Silica Vinyl Ester / Silica Vinyl Ester / Carbon Vinyl Ester / Silica Acids + + ** (+) + + + + + + + + + + + + + Acids that attack SiO² - - - - + + - - (+) + - (+) (+) (+) + (+) Oxidizing Acids (+) (+) (+) (+) (+) (+) (+) + - - + + + + + + Organic Acids - (+) - + + + + (+) + + + + + + + + Water + + + + + + + + + + - + + + + + Salts + + + + + + + (+) + + (+) + + + + + Alcohols (+) (+) - + + + + (+) + + + (+) + + + + Bases + + - + + + + (+) - - - (+) + + + + Oxidants bases - (+) - - - - - (+) - - - + + + + + Aliphatic Solvents (+) (+) - + + + + + + + + + + + + + Aromatic Solvents - (+) - + + + + (+) + + + (+) (+) (+) (+) (+) Ketones - - - + + + + - + + + - - - - - Esters - - - + + + + (+) + + + - - - - - Chlorinated Hydrocarbons - (+) - + + + + - + + + (+) - + - + For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

- ANCOLIT CE

ANCOLIT CE

Line of Anticorrosive Layers, composed of primary paint (PP) and pre-spatulated layer (CE), for uses in sealing and smoothing of counter-floors, new concrete or old sandblasted or milled concrete.

ANCOLIT CE EP1 EP2 VE1 VE2 VET2 Resin / Load Epoxy - Amide / Silica Epoxy - Aminoamina / Silica Vinyl Ester / Silica Vinyl Ester / Conductive Vinyl Ester / Conductive Acids + (+) + + + Acids that attack SiO² - - (+) (+) (+) Oxidizing acids (+) (+) + + + Organic acids - - + + + Water + + + + + Salts + + + + + Alcohols (+) - + + + Bases + - + + + Oxidants bases - - + + + Aliphatic solvents (+) - + + + Aromatic solvents - - (+) (+) (+) Ketones - - - - - Esters - - - - - Chlorinated hydrocarbons - - - - - +: Very good; (+): Normal; - : Not

recommended** including against H2SO4 For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

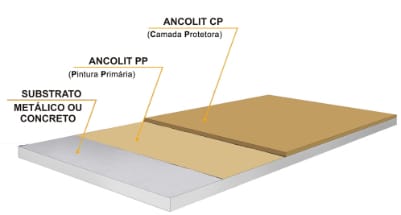

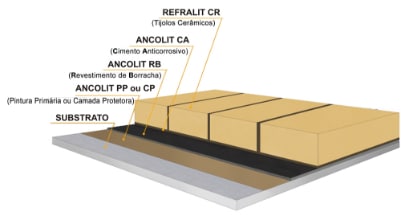

- ANCOLIT CP

ANCOLIT CP

Anticorrosive Protective Layers Line, composed of primary paint (PP) and protective layer (CP), to be used as a single protection or in conjunction with subsequent layers of ceramic or carbon plates or bricks.

ANCOLIT CP EP1 EP2 EP3 EP4 VE1 VE2 VEA1 VEC UP VET1 VET2 EPNF H Resin / Load Epoxy - Amide / Silica Epoxy - Amide / Silica Epoxy - Tar / Silica Epoxy - Amida / Conductive Vinyl Ester / Silica Vinyl Ester / Glass Flakes Vinyl Ester / Silica Vinyl Ester / Carbon INSAT polyester. / Silica Novolac Vinyl Ester / Silica Novolac Vinyl Ester / Glass Flakes Novolac Epoxy / Silica HET Polyester / Silica Acids + + (+) + + + + + + + + + + Acids that attack SiO² - - - (+) (+) (+) (+) + (+) (+) (+) - - Oxidizing acids (+) (+) (+) (+) + + + + + + + (+) + Organic acids - - - - + + + + + + + (+) (+) Water + + + + + + + + + + + + + Salts + + + + + + + + + + + + (+) Alcohols (+) (+) - (+) + + + + (+) + + (+) (+) Bases (+) (+) - (+) + + + + (+) + + + (+) Oxidants bases - - - - + + + + + + + (+) (+) Aliphatic solvents (+) (+) - (+) + + + + + + + (+) + Aromatic solvents (+) (+) - (+) (+) (+) (+) (+) (+) (+) (+) (+) (+) Ketones - - - - - - - - - - - - - Esters - - - - - - - - - - - - (+) Chlorinated hydrocarbons - - - - - - + - (+) + + (+) - +: Very good; (+): Normal; - : Not

recommended** including against H2SO4 For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

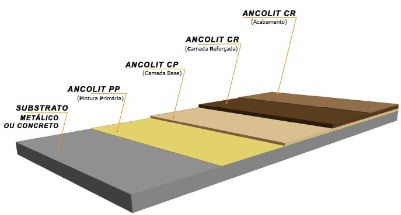

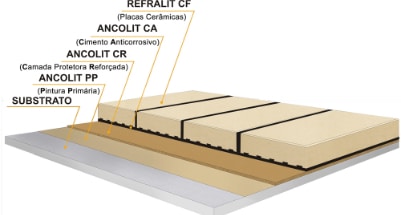

- ANCOLIT CR

ANCOLIT CR

Protective Layers Line Reinforced with fabrics, blankets and “C” glass veil or with

glass scales. The composition of the reinforced layer and the final thickness can be specified according to the data provided in our technical literature.ANCOLIT CR-EPNF

Structured coating system, composed of a laminated monolithic layer, based on novalac epoxy resin and glass or synthetic fibers, composed of reinforcement layer and chemical barrier. It has excellent chemical, thermal and mechanical resistance. Good adhesion to most substrates. It is even indicated where the industrial process is

highly aggressive, as in the case of chemical damage by concentrated sulfuric acid.ANCOLIT CR-VE

It is a structured coating system, composed of a laminated monolithic layer, based on

vinyl ester resin and glass or synthetic fibers, composed of a reinforcement layer and chemical barrier. It has excellent chemical, thermal and mechanical resistance. *ANCOLIT CR-VEA

Laminated monolithic layer, based on vinyl ester resin and glass or synthetic fibers,

composed of reinforcement layer and chemical barrier, which has excellent chemical, thermal and mechanical resistance. *ANCOLIT CR-VEC

Reinforced monolithic layer, thixotropic, based on vinyl ester resin, glass and synthetic fibers and carbon filler, with its thermal expansion coefficient, very close to that of carbon steel and concrete. It has excellent chemical resistance to a wide variety of acids and bases, especially those that corrode silica. Recommended as a protective layer, under carbon plates / bricks or as a reinforced coating, for the protection of floors, channels, pump bases, containment dikes and other objects subject to severe corrosive damage.

ANCOLIT CR-VET

It is a laminated monolithic layer, based on vinyl ester resin and glass or synthetic fibers, composed of reinforcement layer and chemical barrier, which has excellent chemical, thermal and mechanical resistance.*

* It can also be used in combined systems of anticorrosive protection, which is, covered by ceramic or antacid bricks. It is indicated in the corrosion protection of metallic equipment and concrete structures, in chemical, petrochemical, paper and cellulose plants, where the industrial process is highly aggressive.

For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

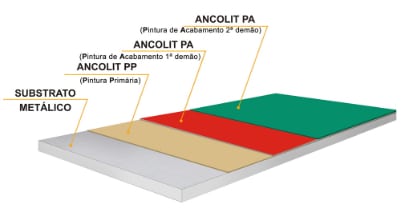

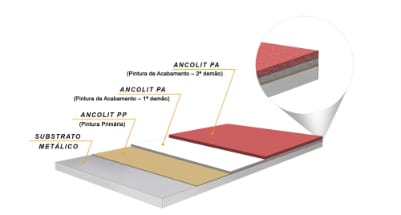

- ANCOLIT PP

ANCOLIT PP

Line of Primary Paintings to be used as a primer for protective layers (CP), reinforced

layers (CR), industrial floors (PI) or as a bonding bridge in direct application with ANCOLIT CA (without intermediate layer) of ceramic tiles or bricks or of carbon.ANCOLIT PP EP1 EP2 EP3 EP4 EP5 EP6 EP7 PU VE1 VE2 VEA1 VET1 VET2 EPNF AS H Resin / Load Epoxy / Amida Epoxy / Amida Epoxy / Tar Epoxy / zinc phosphate Epoxy / Amida Epoxy / Amida Epoxy / Amida Polyurethane Vinyl Ester Vinyl Ester Vinyl Ester Vinyl Ester Vinyl Ester Epoxy Novolac Asphalt HET polyester For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

- ANCOLIT PI

ANCOLIT PI

Line of anti-corrosion industrial floors, composed of primary paint (PP), protective layer (CP) or pre-spatulated leveling layer when necessary (CE), and final layer (PI) with or without finishing paint (PA), used as unique protection on subfloor and new concrete or blasted old concrete.

ANCOLIT PI EP1 EP2 EP3 EP4 EP5 EP6 EP8 EPNF EPNFC VE1 VE2 VE3 VE4 PU1 Resin / Load Epoxy / Silica Epoxy / Silica Epoxy / Silica Epoxy / Silica - Carbon Epoxy / Carbon Epoxy / Silica Epoxy / Silica Novolac Epoxy / Silica Novolac Epoxy / Carbon Vinyl Ester / Silica Vinyl Ester / Carbon Vinyl Ester / Silica Vinyl Ester / Silica Polyurethane / Silica Description Self-leveling Self-leveling Multilayer Self-leveling conductive Carbon load screed Mechanized / screed Screed Screed Screed Multilayer Self-leveling Self-leveling Reinforced Screed Self-leveling Acids + + + + + + + ++ ++ + + + + + Acids that attack SiO² - - - - + - - - + - + (+) - (+) Oxidizing acids (+) (+) (+) (+) (+) (+) (+) (+) (+) + + + + + Organic acids - - - - - - - (+) (+) + + + + (+) Water + + + + + + + + + + + + + + Salts + + + + + + + + + + + + + + Alcohols (+) (+) (+) (+) (+) (+) (+) (+) (+) + + + + - Bases + - + + + + + + + + + + + + Oxidants bases - - - - - - - (+) (+) + + + + + Aliphatic solvents (+) (+) (+) (+) (+) (+) (+) (+) (+) + + + + (+) Aromatic solvents (+) (+) (+) (+) (+) (+) (+) (+) (+) (+) (+) (+) (+) - Ketones - - - - - - - - - - - - - - Esters - - - - - - - - - - - - - - Chlorinated hydrocarbons - - - - - - - (+) (+) - - - - - +: Very good; (+): Normal; - : Not

recommended** including against H2SO4 For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

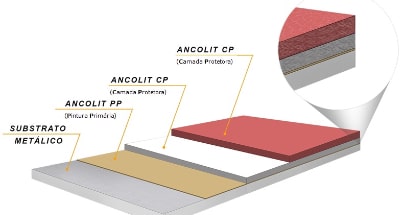

- ANCOLIT PA

ANCOLIT PA

Line of Finishing Paints, used as final painting in protective layers (CP), reinforced layers (CR) or industrial floors (PI) or as painting systems for industrial maintenance paints.

ANCOLIT PA EP1 EP2 EP3 EP4 EP5 EPNF EPNF3 PU VE1 VE2 VE3 VEA3 VET3 Resin / Load Epoxy / Amine Epoxy / Amine Epoxy / Amine Epoxy / Amine Epoxy / Amine Epoxy Novolac Novolac epoxy reinforced with glass scales Aliphatic polyurethane Vinyl ester Vinyl ester reinforced with glass scales Vinyl ester reinforced with glass scales Vinyl ester reinforced with glass scales Vinyl ester reinforced with glass scales Description Finishing Paint High-thickness finishing paint Finishing Paint Finishing Paint Finishing Paint Finishing Paint Finishing Paint Finishing Paint Finishing Paint High-thickness finishing paint Finishing Paint Finishing Paint Finishing Paint For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

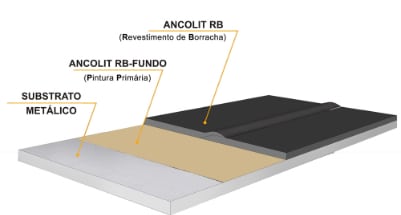

- ANCOLIT RB

ANCOLIT RB

Line of anticorrosive rubber coatings for use as a single protection or as a protective layer under ceramic or carbon plates or bricks.

ANCOLIT RB-CB1

Anti-corrosion and anti-abrasive system based on pre-vulcanized chlorine butyl rubber manufactured in Brazil, using the largest and most modern equipment in the world. Its structure uses a soft rubber sheet in a pre-vulcanized state, manufactured by a continuous extrusion process. It has high adhesion to carbon steel and concrete surfaces and can be applied to protect surfaces subject to severe chemical attacks. It can be used as a single protection or under ceramic or carbon plates and bricks. The ANCOLIT RB-CB1 system is indicated for the protection of objects present in the most diverse industrial sectors, such as chemical and phosphoric acid plants, among others.

ANCOLIT RB-BB1

Pre-vulcanized bromobutyl rubber with two extruded and duplicated layers. It should be used when the chemical environment is highly aggressive.

ANCOLIT RB-BB2

Self-vulcanizing extruded bromobutyl rubber. Used in environments with high chemical

and thermal damages. Vulcanization takes place at room temperature, without the use

of pressure or heat.ANCOLIT RB-BB3

Extruded bromobutyl rubber, posterior vulcanization in autoclave or in-place, under pressure and heat. Used in environments with high chemical and thermal shock, including under vacuum.

For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

- ANCOLIT MA

ANCOLIT MA

Line of auxiliary materials for cleaning, application, reinforcement and other purposes:

ANCOLIT MA Color Description For cleaning Acid Solution Colorless Aqueous Muriatic

Acid Solution (5L water: 1L acid)Solvent A Colorless Acetone type solvent Solvent E Colorless Solvent of the type

Ethyl Alcohol or EthanolSolvent M Colorless Chlorinated

methylene chloride typeSolvent S Colorless Solvent of the

Styrene Monomer typeSolvent T Colorless Thinner general

purpose solventCleaner Colorless Cleaning / diluting

solvent for rubber coatingsFor application AdP Colorless Paraffin-based finishing

additiveSmoothing Colorless Colorless liquid wax Charge T White Thixotropic load of

pyrogenic silica typeEP Acel Amber Curing accelerator for

epoxy systemsEP Ades Gray Teflon film adhesive Film Aa Red Non-stick film for the

ANCOLIT CA line (2 coats)Aa-Soluble Film Light green Non-stick film

for the ANCOLIT CA line, soluble in water (2 coats)Pgm Various White and color pigment

pasteVE Endur White Hardener for polyester /

vinyl ester systemsFor strengthening M450 and M300 White Fiberglass mats in

weights 450 and 300 g / m2T600 and T356 White Fiberglass fabrics

in weights 600 and 356 g / m2TC200 Black Carbon fiber fabric with a

weight of 200 g / m²VVC White Fiberglass veil “C” in weight

30 g / m2VSint White Synthetic veil “Nexus” in weight 37 g / m2 Other purposes CC Black Carbon charge for electrical conductivity Adhesive FC Copper Adhesive copper

tape - for earthing systemPTFE Brown Teflon film treated on both sides Joint B and Joint S Gray Two-component

elastic cements for expansion jointsMastic Black Pasty mortar for non-rigid, waterproof adhesion Flex Gray Two-component elastic compound for flexible waterproofing Cond1 Black Conductive load for use in the PP line (Primary Paintings) Cond2 Black Conductive charge for use with ANCOLIT CP-EP1 Q1 Sand Mineral load for mechanical anchoring granulometry 1 (fine) Q2 Sand Mineral load for mechanical

anchoring granulometry 2 (coarse)QR Pale sand Mineral load for mechanical

anchoring (multilayer)For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

- REFRALIT

REFRALIT

Line refractory bricks and plates used in heavy anticorrosive coatings especially in acidic environments and / or alkaline specified in terms of their physical and chemical characteristics.

CARBOLIT CV / CVT CF CC CCi Brick Type / Manufacturing process Coated Coated Sintered Impregnated Sintered Dimensions and weight Thickness (mm) 30 50 65 75 30 50 65 75 30 50 65 75 30 50 65 75 Length (mm) 240 240 240 240 240 240 240 240 240 240 240 240 240 240 240 240 Width (mm) 115 115 115 115 115 115 115 115 115 115 115 115 115 115 115 115 Weight (kg) approx. 1,2 2,0 2,6 3,0 1,1 1,9 2,4 2,8 1,3 2,2 2,9 3,3 1,3 2,2 2,9 3,3 Guiding chemical resistance m * Acids Bases + + + + + + + + Acids that attack SiO² Oxidants Bases + + + - + + + + Oxidizing acids Aliphatic Solvents + + (+) + + + + + Organic acids Aromatic solvents + (+) + + + + + + Water Ketones + - + + + + + + Salts Esters + - + + + + + + Alcohols Chlorinated hydrocarbon + - + + + + + + OBS .: different dimensions can be provided

on request. Carbolit CV and CF may be

provided in special parts "L", "J" or other.* Guiding data - due to the variety of uses,

no reclaim can be accepted.For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

- CARBOLIT

CARBOLIT

Carbon plates and bricks line used in heavy anticorrosive coatings especially in environments that attack SiO2 (Silica), specified according to their physical and chemical characteristics.

REFRALIT CF CR CA Type plate / Brick Ceramic anti acid Ceramic anti acid Anti alkali compound Dimensions and weight Thickness (mm) 14 17 30 40 32 38 63 76 30 50 65 Length (mm) 240 240 240 240 229 229 229 229 240 240 240 Width (mm) 115 115 115 115 114 114 114 114 115 115 115 Weight (kg) approx. 0,8 0,9 1,9 2,5 1,9 2,2 3,7 4,4 2,0 3,3 4,3 Resist. química orientativa * Acids Bases + (+) + (+) - + Acids that attack SiO² Oxidizing Bases - (+) - (+) - - Oxidizing acids Aliphatic Solvents + + + + - + Organic acids Aromatic solvents + + + + - + Water Ketones + + + + + + Salts Esters + + + + (+) + Alcohols Chlorinated hydrocarbon + + + + + - Confor-mation Format / Details parallel parallel parallel

with socketBottom face with claws smooth or

groovedsmooth or

groovedNote. Other dimensions and pieces formed

upon request.* Guiding data - due to the variety of uses,

no reclaim can be accepted.For more technical information visit the literature page and get to know our FT’s (technical sheets) and FTI’s (technical and application instruction sheets). If you do not find the necessary information, contact our technical team: (19) 3729-3070.

Chemical and Petrochemical Industries

Known as “the industry of industries” for serving the most varied segments…

VIEW MORE

Mining

Mining corresponds to an economic and industrial activity that consists of research,…

VIEW MOREThermoelectric power plants

Thermoelectric plant is an industrial facility used to generate electric energy from…

VIEW MORE

Pulp and Paper Plants

The institution that serves for the fabrication and manufacture of different types…

VIEW MORE

Fertilizer Industries

The fertilizer industry is basically intended for the production and sale of…

VIEW MORE